What is filter?

An optical filter refers to one or more dielectric films or metal films coated on an optical element or an independent substrate to change the characteristics of light wave transmission. Utilize the characteristic changes caused by light waves in the transmission of these films, such as transmission, absorption, scattering, reflection, polarization, phase changes, etc., and then design and manufacture various filter products to achieve scientific and engineering application purposes.

The production and manufacturing of optical filters is a complex engineering technology that involves many professional technical fields, including vacuum acquisition technology, vacuum measurement technology, computer-aided design technology, optical property detection technology, electronic circuit technology, material property detection and preparation Technology etc.

Types of filters

category | content |

Spectral band | UV filter, visible filter, infrared filter |

Spectral characteristis | Bandpass filters, cutoff filters, spectroscopic filters, neutral density filters, reflection filters |

Film material | Soft film filter, hard film filter |

Bandpass type | Narrowband filters, broadband filters |

Short wave pass type (low wave pass) | Light shorter than the selected wavelength is passed and light longer than the wavelength is blocked, such as an infrared cut filter |

Long wave pass type (high wave pass) | Light longer than the selected wavelength passes and light shorter than the wavelength is cut off, such as an infrared transmission filter |

Filter process and quality control system

In the field of optical components, MFrontier focuses on the design and development of mid- and far-infrared band filters, and has built infrared long-pass filters, band-pass filters, narrow-band filters, anti-reflection filters, metallized light windows,etc.

Infrared bandpass filter

A filter with cutoff areas on both sides of the transmission band of the spectral characteristic curve is called a bandpass filter, which is often used to transmit a part of the spectrum while cutting off all other wavelengths. Bandpass filters are an important type of optical thin film components.

Features

High transmittance, high cut-off depth, low temperature bleaching, firm film layer

Application

Infrared detector, infrared gas analyzer, security monitoring, medical equipment, industrial temperature measurement

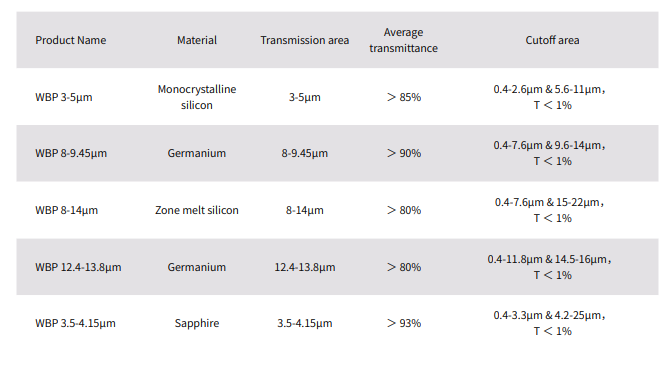

Part of the product:

Infrared narrowband filter

Infrared narrow-band filters allow light signals to pass through in a specific wavelength band, while blocking light signals on both sides that deviate from this band. The passband of a narrow-band filter is relatively narrow, generally less than 5% of the central wavelength value.

Features

High transmittance, high cut-off depth, low temperature drift, accurate center wavelength, firm film layer

Application

Instrumentation, Biochemical Analysis, Optical Instruments, Spectral Measurement, Gas Detection

Part of the product:

AR filters

Infrared anti-reflection coating is an optical film deposited on the surface of optical components to reduce surface reflection and increase the transmittance of the optical system. It improves contrast by reducing scattered light in the system.

MFrontier can provide lenses, lens coatings, lens + sleeve designs, lens + sleeve + sensor and other combinations for shipment according to customer needs.

Features

High transmittance, firm membrane, complete facilities

Application

Industrial temperature measurement, power inspection, aerospace precision remote sensing, infrared thermal imaging system

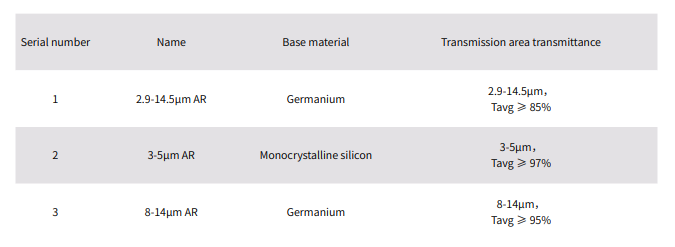

part of the product

Metalized light windows

Metallized light windows are coated with metal films (such as chromium, nickel, gold) on the edges of sapphire, germanium or silicon substrates for welding to achieve airtight packaging. The light-passing area is coated with a filter film and can be directly welded or installed on Opto-mechanical assembly.

Features

Metalized packaging has good airtightness, High stability, Strong aging resistance, Can be used in extremely harsh environments

Application

Infrared detectors, Medical endoscopes, Vacuum observation windows, Various optical windows

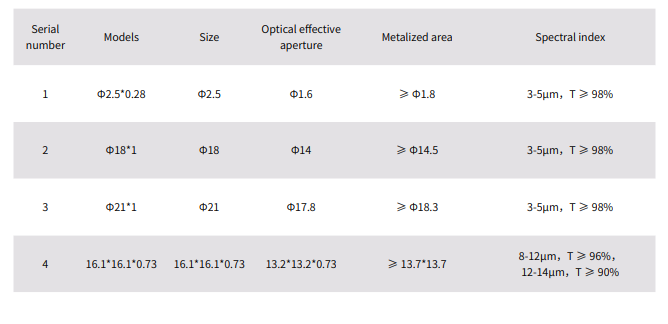

Part of the product:

Relying on the complete optical component core preparation process & quality control system, high-quality substrates, cleaning, coating processes, coating film layer design, coating environment, cutting, quality inspection and other strict preparation processes, MFrontier can manufacture monocrystalline silicon, germanium, sapphire, calcium fluoride, zinc selenide and other base materials are plated on most optical films. Special films can also be developed according to customer needs ,such as material, size to meet the needs of enterprises.

Share