Refrigerant is the medium substance used to complete energy conversion in various heat engines, mainly fluorine-containing refrigerants. The refrigerant can be a gas, liquid or mixture. It absorbs and releases heat through processes such as heat absorption, compression, condensation and expansion, thereby achieving the refrigeration effect.

In March 1985, 28 countries adopted and signed the Vienna Convention for the Protection of the Ozone Layer. In September 1987, the Montreal Protocol was adopted. Its main goal is to strive to control the total global production and consumption of ozone-depleting substances, protect the ozone layer, and promote the replacement of global fluorine refrigerants to achieve sustainable development.

On October 15, 2016, at the 28th Meeting of the Parties to the Montreal Protocol on Substances that Deplete the Ozone Layer, held in Kigali, the capital of Rwanda, countries agreed on the Kigali Amendment to phase out hydrofluorocarbons.

Global fluorine refrigerant upgrading, zero ODP and low GWP are the development trends

Refrigerant safety levels and applications

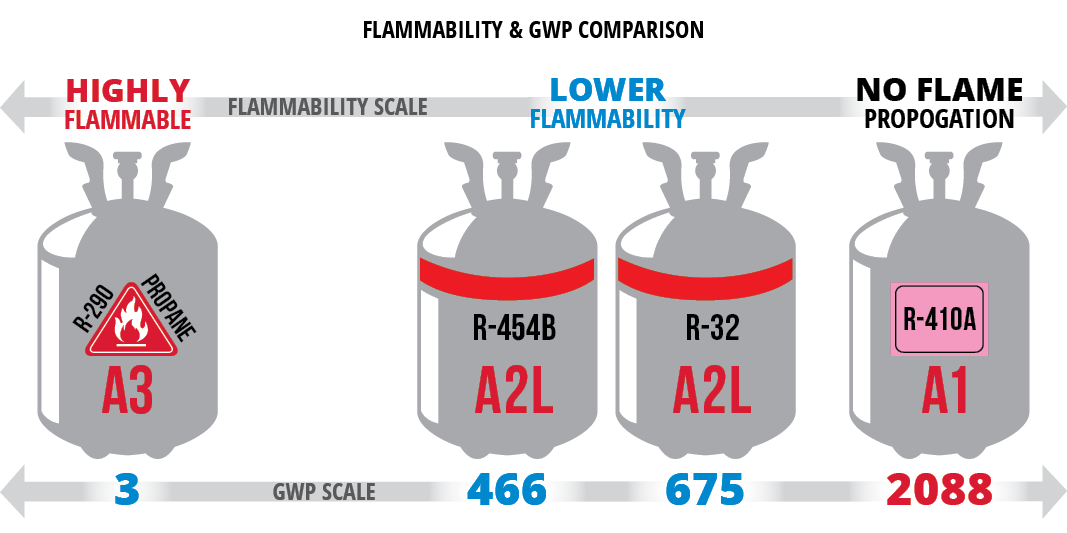

The safety of refrigerants mainly includes toxicity and flammability. The national standard "Refrigerant Numbering Method and Safety Classification" GB/T 7778-2017 divides the toxicity of refrigerants into Class A low chronic toxicity and Class B high chronic toxicity.The flammability is divided into Category 1 no flame spread, Category 2L weakly flammable, Category 2 combustible, and Category 3 flammable and explosive. According to GB/T 778-2017, the safety of refrigerants is subdivided into 8 categories: A1, A2L, A2, A3, B1, B2L, B2, and B3. Among them, A1 is the safest and B3 is the most dangerous.

At present, air conditioners and automobiles are the main application areas for refrigerant demand, and the maintenance market accounts for a relatively high proportion. Fluorine refrigerants are mainly used in household appliances, automotive air conditioners and thermal management, heat pumps and other scenarios. Air conditioning refrigerants are mainly R22, R32, and R410a (50% blend of R32 and R125 each), and automotive refrigerants are mainly R134a and R1234yf. R600a environmentally friendly hydrocarbon refrigerant has been widely used in refrigerators, freezers and other fields. According to Kaiyuan Securities estimates, among the various downstream applications of fluorinated refrigerants, demand for air conditioners, automobiles, and other fields (cold storage, cold chain, fire extinguishing agents, etc.) account for approximately 57%, 22%, and 21% respectively. Among them, the demand for refrigerants in the air-conditioning production and sales market and the maintenance market accounted for approximately 31% and 69% respectively; the demand for refrigerants in the automobile production and sales market and the maintenance market accounted for approximately 26% and 74% respectively.

The application of refrigerant has been closely related to people's daily life. Once the refrigerant leaks, it will endanger people's property and life safety.

Refrigerant leak detection is necessary! Commonly used refrigerant leakage detection technology principles mainly include the following categories:

The core component of refrigerant leakage detection is the refrigerant leakage monitoring sensor. Currently, sensors for A2L weak flammable refrigerant leakage monitoring mainly include non-dispersive infrared (NDIR), metal oxide semiconductor, and thermal conductivity technology.

Compared with sonic technology, thermal conductivity, and semiconductor technology, NDIR non-dispersive infrared technology utilizes the characteristics of combustible gases to absorb infrared rays of specific wavelengths. It has high gas selectivity, does not react to gases other than combustible gases, and has high detection accuracy. Due to the advantages of good stability and long service life, the number of air conditioning manufacturers using NDIR technology detection principles has increased in recent years.

The Mfrontier MGS11 precision small refrigerant sensor adopts the NDIR non-dispersive infrared technology absorption principle, combined with a high-precision sampling circuit, and has built-in temperature compensation and self-calibration functions. It can conduct real-time online monitoring of the refrigerant gas concentration in the environment to ensure the safety of users' lives and property. Can be widely used in refrigerant leakage detection of commercial air conditioners, central air conditioners, refrigeration units and other products.

Product advantages

Passed IEC/UL (60335-2-40 Appendix LL) certification

MGS11 precision small refrigerant sensor response time, calibration and short-term stability, gas selectivity test and poisoning test, refrigerant poisoning and oil mist test, long-term stability test, temperature test, temperature test, air pressure test and other test items all meet the standards. Suitable for safety experiments and testing of different refrigerant leakage detection products, such as R32, R410A, R454B, R1234yf, R1234ze, etc.

High tolerance, high reliability

Industry’s widest operating temperature range

Automotive grade electromagnetic compatibility design

NDIR principle has good gas selectivity

Miniaturization

Compact and reliable, saving space for greater functionality

Save energy

A variety of models and appearances to meet the diverse needs of end product structural design

Full industry coverage

Specifications,

Multiple output methods,

Multiple measurement methods,

Freely matched to meet the application needs of various industries. With the replacement of third- and fourth-generation refrigerants, the global air-conditioning market continues to grow. Industries such as cold chain, heat pump, new energy vehicles will open up demand for refrigerants, and the application fields of refrigerant monitoring sensors will become wider and wider. The MGS11 series of precision small refrigerant sensors can monitor the leakage of weakly flammable refrigerants such as R32, R410A, R454B, R1234yf, R1234ze, etc. Protect people's daily health, property and life safety.

With the replacement of third- and fourth-generation refrigerants, the global air-conditioning market continues to grow. Industries such as cold chain, heat pump, new energy vehicles will open up demand for refrigerants, and the application fields of refrigerant monitoring sensors will become wider and wider. The MGS11 series of precision small refrigerant sensors can monitor the leakage of weakly flammable refrigerants such as R32, R410A, R454B, R1234yf, R1234ze, etc. Protect people's daily health, property and life safety.

Share